Processing of Sencha

Asamushi Sencha |  Chumushi Sencha |  Fukamushi Sencha |

| After picking, the fresh tea leaves undergo the primary processing processes which are performed by the farmer on the day the leaves are picked. The primary processing steps are 1) fanning, 2) steaming, 3) cooling, 4) kneading and 5) drying. Tea leaves which are processed in these ways are known as Aracha, the semi-finished product of crude tea. Crude tea is not sold to end users as the leaves are of non-uniform shape and sizes, have a unrefined 'grassy' aroma and they contain too much moisture which is not suitable for long-term storage. Aracha thus has to undergo the secondary processing steps which are carried out by the tea wholesaler before it can be sold as the finished product, Sencha. The secondary processing steps include 1) blending, 2) cutting and sorting and 3) drying. |

PRIMARY PROCESSING - ARACHA

| Freshly picked tea leaves oxidize quickly if left unattended. This causes the leaves to loose its quality and freshness. To prevent this, tea leaves are fanned with a damp air, enabling the leaves to maintain their moisture and simultaneously dissipate the heat given off by the live fresh leaves (the heat comes from the heat of the sun). |

2) STEAMING

| Freshly picked tea leaves are steamed within 24 hours after harvest to halt enzymatic oxidation, which preserves the green color of the leaves and removes the 'grassy' smell. The duration of the steaming process determines the final flavor, color and aroma of the tea. Hence, this is a process which requires the expertise and experiences of the farmer in determining the right steaming temperature and length of steaming based solely on the condition of the fresh tea leaves, which differs from crop to crop. |

| Generally, there are five types of steaming, namely Asamushi (light steaming, 30 seconds), Chumushi (medium steaming, 60 seconds), Fukamushi (deep steaming, 90 seconds), Jomushi (special deep steaming, 120 seconds) and Kyokumushi ( extra deep steaming, 140 to 160 seconds). A short steaming time will yield leaves which are unbroken and which bear a profound green color. The tea will be highly aromatic. On the contrary, a long steaming time will cause the leaves to become more broken as the cellular membrane breaks down easily during the later processing. The leaves will appear lighter in color with less aroma. |

The Effect of Steaming Time on Tea Leaves

| TYPE | CONDITION OF LEAVES | LIQUOR | FLAVOR / AROMA |

| Asamushi (Light Steaming, 30s) | Long, narrow uniform shape, unbroken. | Golden Clear with no residues | Clean clear taste with a certain degree of astringency / Highly aromatic |

| Chumushi Sencha (Medium Steaming, 60s) | Pin-shape, a little broken | Fresh green with little residues | Slightly rich umami taste / Less strong aroma |

| Fukamushi Sencha (Deep Steaming, 90s) | Broken, appear dusty | Darker green with with residues | Rich umami taste / Weak aroma |

3) COOLING

| The steamed tea leaves are cooled to room temperature by applying a flow of dry, hot wind on the leaves immediately after the leaves emerge from the steamer. Steamed tea leaves will loose their color, flavor and aroma if not cooled immediately. This process also removes steam dews from the surface of the leaves, which speeds up the drying effect in the later processing steps. |

4) KNEADING

|

|

| The primary purpose of kneading is to dry and shape the tea leaves. The kneading process involves four stages of kneading, namely, 1) Soju Kneading (粗揉), 2) Junen Kneading (揉捻), 3) Chuju Kneading (中揉) and 4) Seiju Kneading (精揉). All stages involve some crushing and rubbing of the leaves. This causes the cell walls of the tea leaves to break up, thus allowing the nutrients and flavor of the tea leaves to infuse better in water. 1) Soju Kneading (粗揉) Kneading with light rubbing and crushing is conducted under warm dry air to bring down the water content of the tea leaves and soften the tea leaves. Moisture loss is rapid and uniform. 2) Junen Kneading (柔捻) At this stage, the tea leaves are kneaded without using any heat. The tea leaves are kneaded to cause the cell walls to break up so that the nutrients can infuse easily in water. The kneading also aims at achieving uniform water content in all the leaves as the thicker parts, like stems take longer time to loose moisture than the blades of the tea leaves. To achieve this, the leaves are kneaded into a ball. The time and strength of kneading depends on the tenderness of the tea leaves. The younger the leaves are, the lesser time and strength of kneading is required. 3) Chuju Kneading (中揉) After going through the second stage Junen kneading, the tea leaves have become withered with uneven shapes and the water content is still high. To remove moisture further, kneading at this stage is carried out under warm dry air. The tea leaves are dried and kneaded lightly to loosen them up to ease the final kneading process which gives the leaves their characteristic fine needle-like shape. 4) Seiju Kneading (精揉) This is the final stage of kneading which kneads the leaves in a back and forth movement, giving the leaves their characteristic fine needle-like shape. Moisture is removed further by using heat from burners located under the Seiju Kneading machine. |

| The tea leaves are dried by using hot-air drying to reduce the moisture content to about 5%. This is a vital condition for long-term storing. After this stage of drying, the end-product is known as Aracha, or crude tea leaves. |

SECONDARY PROCESSING - SENCHA

| Secondary processing involves blending, pan firing, cutting / sorting and grading. Secondary processing methods and procedures are highly complex and differs from region to region, factory to factory. Generally, secondary processing methods and procedures are decided based on the specification of the tea, which is in accordance to the color, taste and aroma requirements. Consumers in different regions of Japan have different taste requirements. This implies that the final product after the primary and secondary processing has to meet the taste requirement of the consumers in order to sell well. It is a known fact that it requires good secondary processing skills of experienced workers to produce good tea. Without a good secondary processing skill, even the highest quality crude tea, Aracha, will not yield a high quality Sencha. |

1) BLENDING

| Blending refers to the blending of the different cultivars of green tea leaves to obtain a tea of a specific taste and flavor. This method is adopted to meet the different requirements for taste and pricing of consumers in different regions of Japan. |

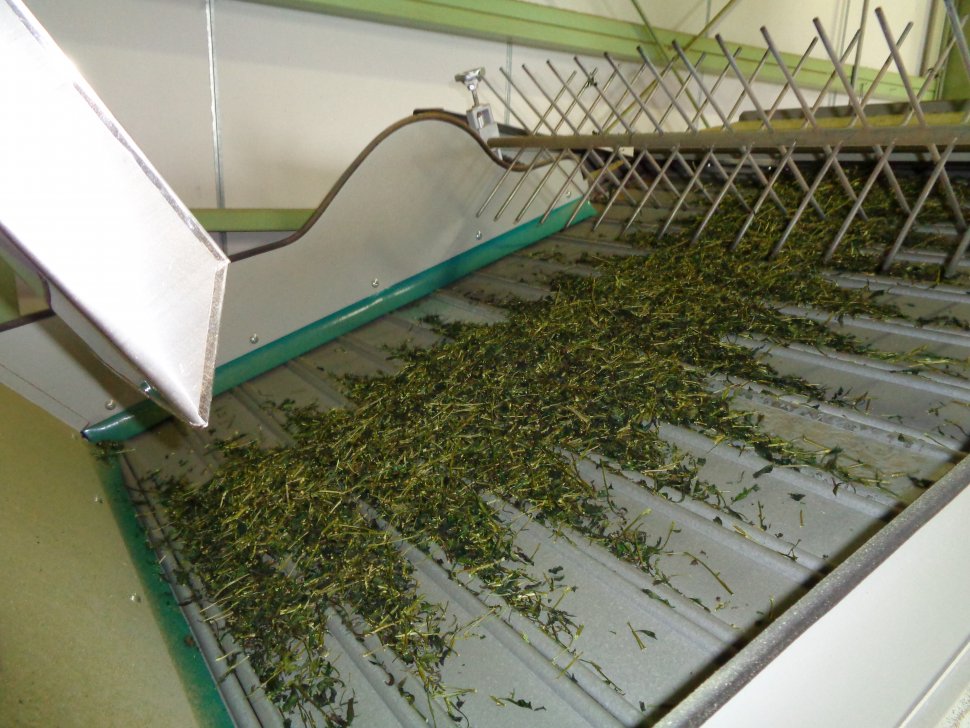

2) CUTTING / SORTING

| Aracha processed by the farmer contains whole-leaf tea leaves, powdered tea leaves, fannings and stems. The tea wholesaler has to separate these parts as each part is used to produce different teas. The sorting machine uses air to blow and separate the lighter fannings and powdered tea leaves from the heavier whole-leaf tea leaves and stems. It also has a sieve whereby any leaves which are smaller than the meshes of the sieve will fall through them, thus separating leaves which are not within the standard size. |

3) DRYING

| This final drying process performed by the tea wholesaler is literally also known as 'firing'. The Aracha is dried to reduce the moisture content in the leaves to 3%. Firing determines the aroma and taste of the finished product, hence the expertise of the person carrying out the process is highly called for. It is a known fact that a high grade Aracha will not yield a premium grade Sencha without a good firing skill. Dryers come in different forms. The type of dryer to be used is decided by the end color, taste and aroma of the tea to be produced. |